BIOPLASTICS

Empowers bioplastics to break through industry barriers with a

high performance-low dosage additive

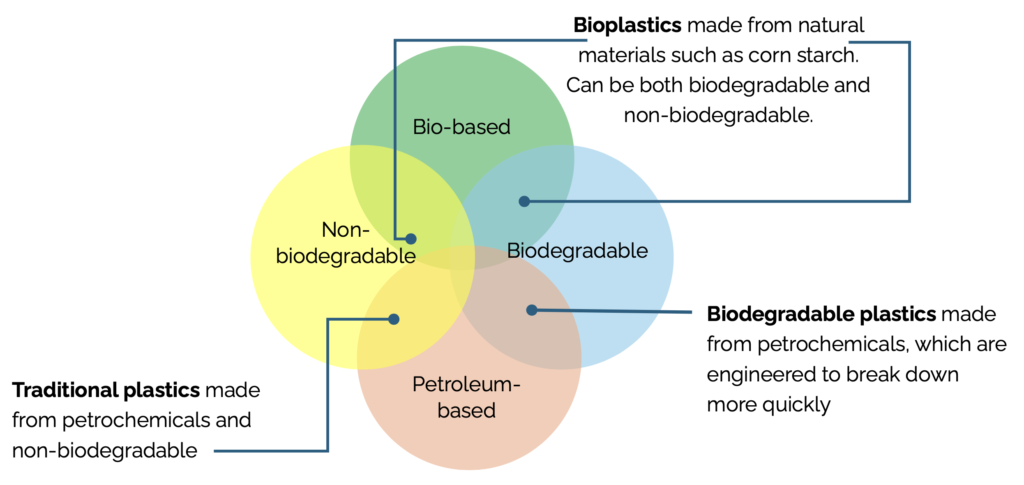

Strong, lightweight, and moldable, plastics are used in thousands of products that add comfort, convenience, and safety to our everyday lives. Plastic technology has helped us to prevent food waste, made our cars lighter and more fuel efficient, and allows the electronic industry the agility to meet the evolving needs of a digital world.

improves their processibility, efficiency, and scalability,

making them a viable and sustainable alternative to traditional plastic.

With the shift of regulatory frameworks and consumer expectations, sustainability has become integral to company core business strategies, and many have begun their transformation, understanding that long-term success hinges on their ability to operate responsibly within environmental realms.

Manufacturers are striving to reduce their environmental footprint by implementing recycling programs, reducing energy and natural gas consumption, and reformulating their products with cleaner, non polluting ingredients.

Bioplastics offer sustainable alternatives for the food packaging industry, where single-use plastic is most consumed.

Industry adoption has been slow to pick them up since they don’t deliver performance or cost effectiveness as well as traditional plastics do but even the traditional kind is trying to go greener.

DextraCel® can help the planet co-exist with plastic in a more sustainable way.

DextraCel® provides a 100% bio-sourced and biodegradable, high performance nucleating agent that helps bridge the gaps in bioplastics, including:

processibility, strength performance, flexibility, and versatility.

What is the nucleating agent and why does it matter?

The formation of plastic requires the polymer to be melted so it can be crystalized and become a solid material during the cooling process and take its intended shape.

The nucleating agent serves to increase the rate of crystallization while controlling the changes in properties during the transition, like density and clarity.

By delivering a higher crystallization temperature and rate in a low dosage (<0.2%), DextraCel® improves processibility, efficiency, and scalability of the material production.